Digitalyoke’s Cloud ERP for manufacturing delivers end-to-end visibility and automation across your production lifecycle. From demand planning and material requirements to quality checks and delivery, teams gain real-time insights that eliminate manual bottlenecks and ensure on-time results.

Key Benefits:

End-to-end production visibility from planning through delivery

Automated material planning and dynamic scheduling

Integrated quality and compliance tracking

Predictive maintenance to maximize equipment uptime

Real-time analytics and collaborative supplier portal

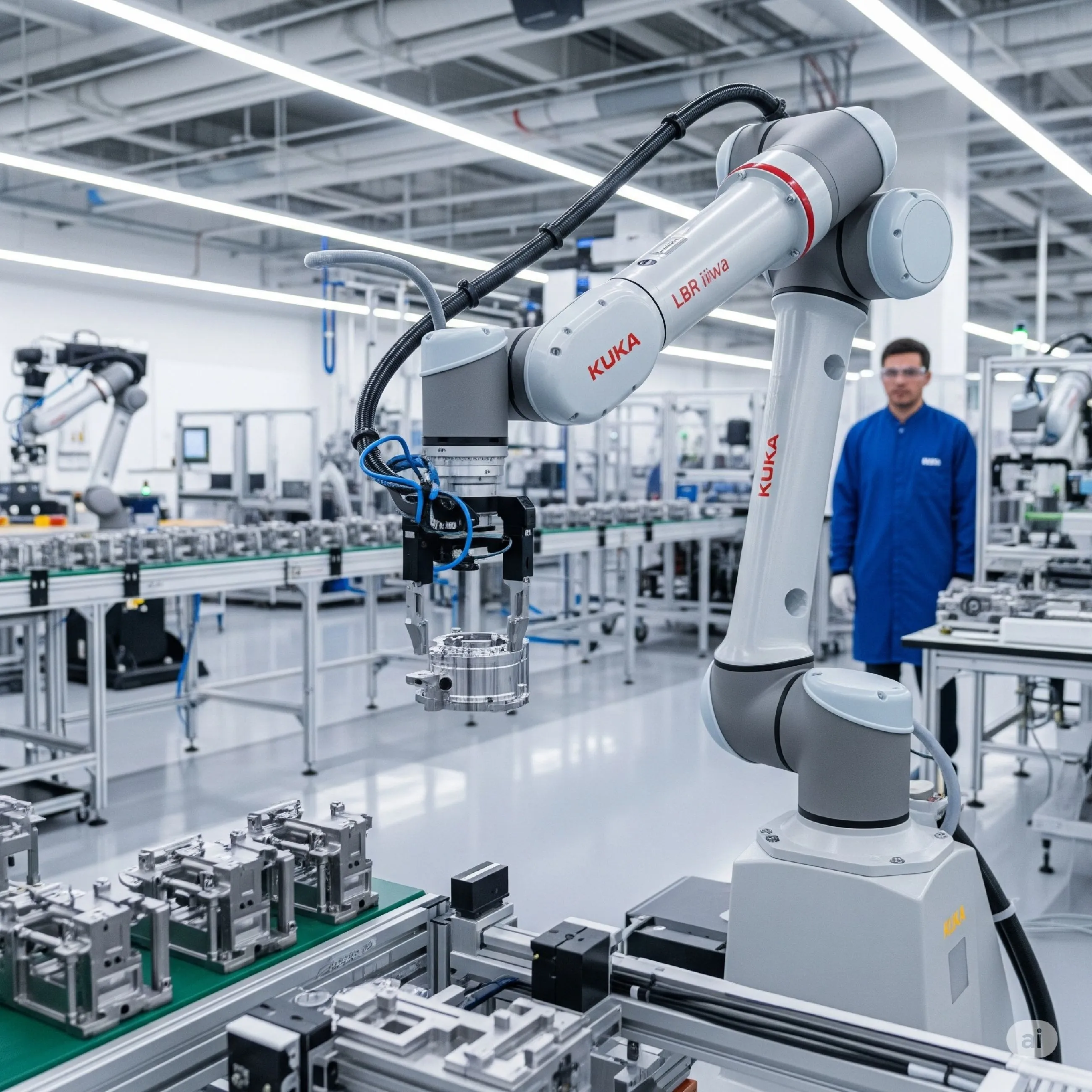

Our proven six-step implementation—discovery, pilot deployment, configuration, training, go-live support, and enterprise rollout—ensures rapid adoption with minimal disruption. Subscription-based pricing delivers clear ROI, typically in 6–12 months through lower inventory costs and reduced downtime.

Forecasts demand and aligns procurement with production to minimize stock-outs and cut inventory costs.

Optimizes machine and labor allocation in real time to speed lead times and clear bottlenecks.

Provides unified stock visibility, smart bin assignments, and auto-reorder triggers to boost picking accuracy and lower carrying costs.

Live dashboards track throughput, yield, and quality, delivering instant insights for continuous improvement.

Pay-as-you-go subscriptions cut hardware and IT costs, making enterprise functionality affordable for any business size.

Log in from anywhere—office, home, or mobile—with seamless updates and real-time collaboration.

Deploy in weeks with automatic updates and 24/7 support for rapid ROI and uninterrupted operations.